Concrete Crusher

Hire Mobile Concrete Crushers for Site Waste Recycling

At Kingspit Transport, we offer reliable, high-performance concrete crusher hire to domestic, commercial, and industrial clients across Kent, Surrey, Sussex, and the wider South East. From our depot in Petworth, we deliver mobile jaw crushers directly to your site, allowing you to recycle concrete and rubble on-site, reduce waste, and generate reusable aggregate.

Our concrete crushers are suitable for construction, demolition, groundworks, landscaping, and infrastructure projects of all sizes. We also provide UK-wide delivery for large or long-term contracts.

HEAD OFFICE

01798 343764

OFFICE HOURS

8:00am – 5:00pm

Mon – Sat

MOBILE

07860 398295

HEAD OFFICE

01798 343764

MOBILE

07860 398295

OFFICE HOURS

8:00am – 5:00pm

Mon – Fri

Concrete Crushers Available from Kingspit Transport

At Kingspit Transport, we supply two powerful, mobile jaw crushers – the Pegson Metrotrack HA and the McCloskey J40 – selected to suit a wide range of construction, demolition, and site clearance projects. Whether you’re working on a tight residential plot or a large commercial redevelopment, our crushers help you efficiently process concrete, bricks, and rubble into reusable sub-base or backfill material.

Our machines are available for short or long-term hire, with or without an operator, and can be delivered directly to your site anywhere in the South East or nationwide.

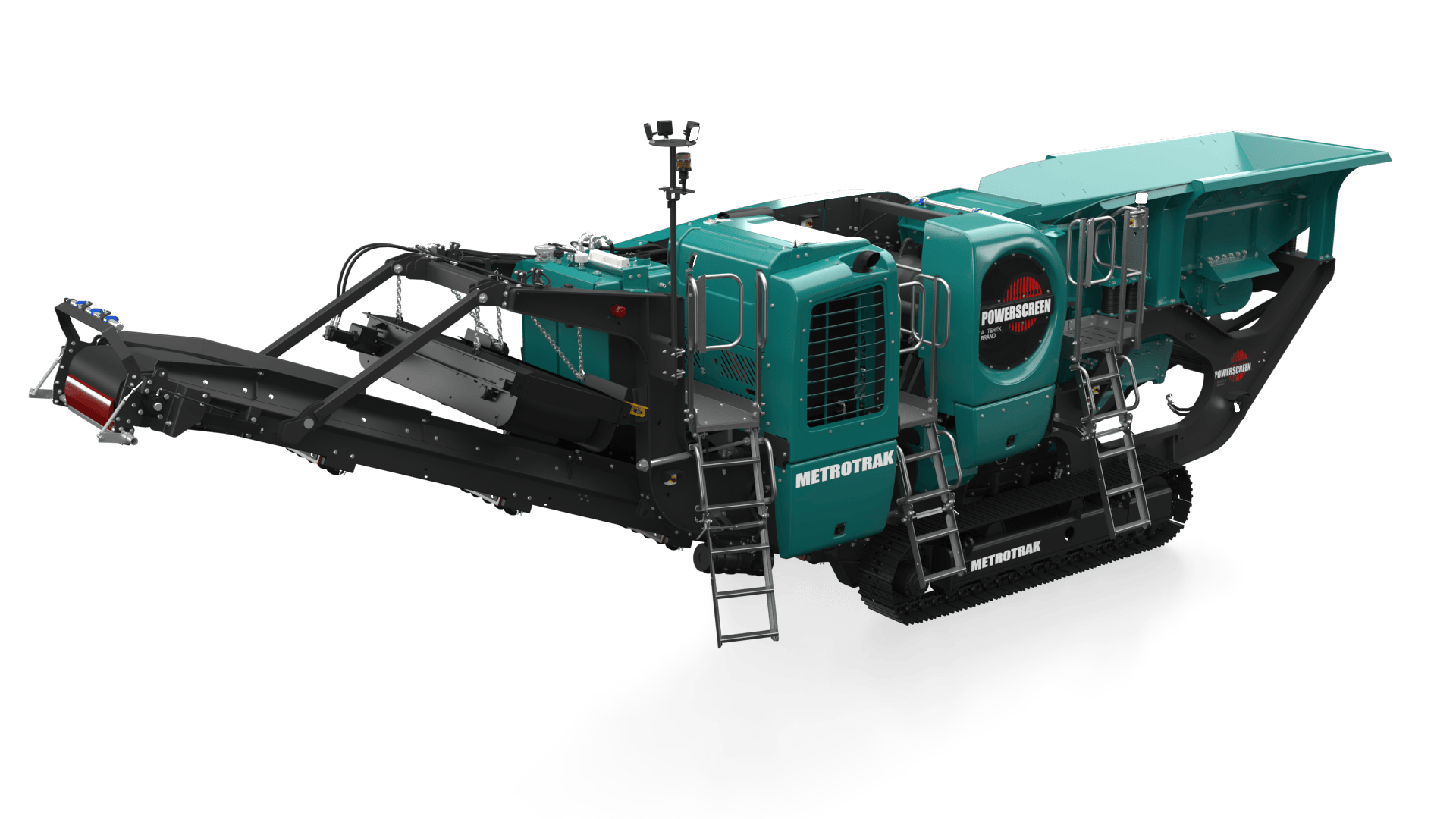

Pegson Metrotrak HA – High Output for Heavy-Duty Jobs

The Pegson Metrotrak HA is a high-performance, track-mounted mobile jaw crusher built to handle demanding concrete and demolition waste applications. Designed for crushing tough and abrasive materials, this compact machine is fully mobile, fuel-efficient, and equipped with a hydraulic jaw adjustment for maximum productivity. This machine is well-suited for groundworks contractors, demolition companies, and large-scale infrastructure projects that require durable equipment and maximum productivity.

The Pegson Metrotrak HA is a tracked jaw crusher designed to handle concrete, blocks, slabs, kerbstones, setts, natural stone, bricks, and rubble from construction and demolition sites. It is ideal for processing a wide range of materials including construction and demolition waste, reinforced concrete, bricks, blocks, slabs, natural stone, rubble, and aggregates. Their compact design makes them especially well-suited to work in urban environments and tight-access sites where larger equipment isn’t practical.

Key Features

Technical Specifications

Applications

McCloskey J40 – Compact & Efficient

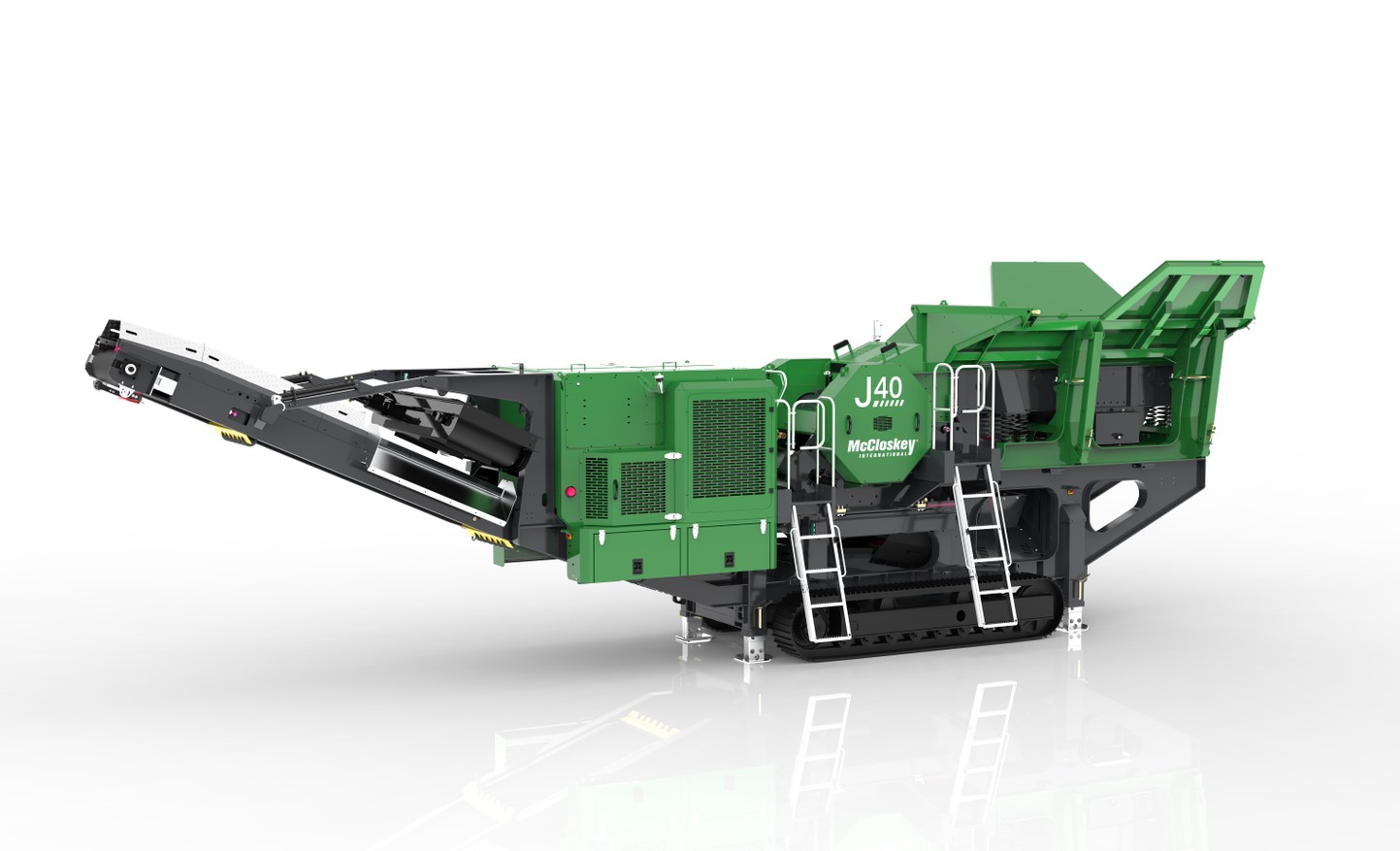

The McCloskey J40 is a compact and powerful mobile jaw crusher, widely recognised for its durability, mobility, and high productivity. Built with a deep jaw chamber, rugged I-beam chassis, and heavy-duty cheekplates, it delivers efficient crushing performance in a wide range of applications. Ideal for sites with tight-access, the J40 is easy to transport and quick to set up—taking just 10 minutes to get to work. With a fast jaw speed, user-friendly diagnostics, adjustable CSS while in operation, and an open chassis design for easy maintenance, the J40 reduces downtime and increases on-site efficiency. Optional features like the overband magnet, side conveyor, and jacking legs enhance versatility and make this crusher a reliable choice for contractors and operators working in demanding conditions.

Key Features

Technical Specifications

Applications

REQUEST A CALLBACK

Please leave your contact details and we’ll call you back.

HEAD OFFICE

01798 343764

OFFICE HOURS

8:00am – 5:00pm

Mon – Sat

MOBILE

07860 398295

HEAD OFFICE

01798 343764

MOBILE

07860 398295

OFFICE HOURS